Platinum paste, as a precious metal electronic paste, holds an extremely important position. The following is a discussion on the issues related to platinum paste.

How is the platinum slurry applied and used?

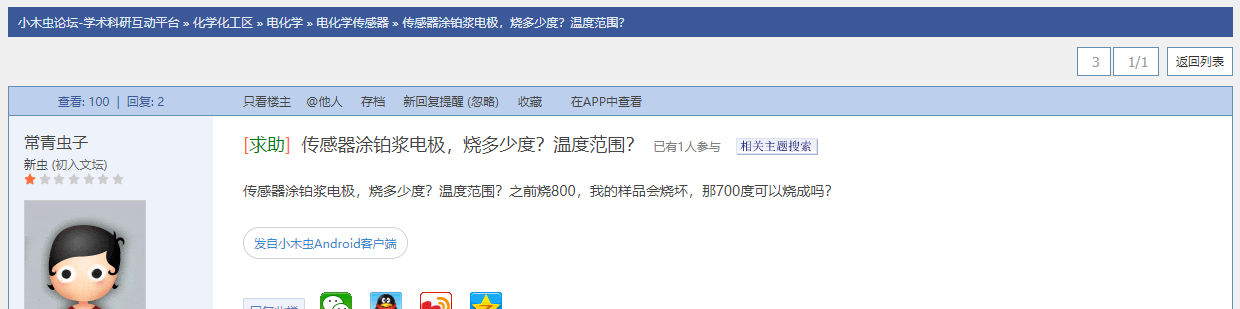

What is the sintering temperature for platinum paste? What is the minimum temperature needed to achieve sintering? And what is the maximum temperature that won't cause damage?

What are the various uses of platinum paste?

What issues should be paid attention to during the platinum paste process?

The platinum paste needs to work under high temperatures for a long time. Will there be any problems? What kinds of situations might occur?

What are the common problems that occur during the use of platinum paste?

The platinum paste is a uniform paste-like material formed by mixing pure platinum particles, organic substances and binders. Platinum has extremely stable metallic properties and plays a crucial role in sensor electrodes and high-temperature co-fired components.

In terms of its usage, there are often cases where people are unsure. For instance, the question on Xiaowuzhong.com is a typical example.

For most application scenarios, the screen printing process is generally used to achieve uniform and clear electrode patterns. Try to avoid the application of the coating method, as the thickness of the film layer is uneven, the lines are not clear, and there are many problems after sintering. In the mild cases, the resistance groups are not uniform, and the film layer has cracks. In severe cases, it will peel off from the substrate and cannot form an ideal conductive layer.

After printing, it is heated at 150℃ for 10 minutes. The temperature is increased by 5-8℃ per minute, with the peak temperature reaching a minimum of 850℃ for 10 minutes. This is the minimum requirement for the complete sintering of the platinum paste. However, sometimes due to various constraints, it is not allowed to reach such a high temperature. What happens if the sintering is done at a temperature lower than 850℃? I conducted experiments and found that when it was sintered to 800℃, the test results showed that it could be metallized, but the resistance was relatively high, and the adhesion was not very reliable. If the requirements are not very high, it can be used with some compromise. Lower the temperature to 750℃ and conduct the sintering test. Basically, it is not usable. In fact, to achieve better sintering results, a higher sintering temperature of 950℃ is required for the film layer to reach the best condition, and the resistance will also be smaller. Using the platinum paste in many cases requires the stability of platinum at high temperatures. Therefore, the platinum paste can be sintered up to 1400-1500℃, and the film layer will still be relatively stable. When using it, different sintering temperatures can be selected according to the needs, and the platinum paste can handle all of them.

The working temperature of most components usually ranges from -20 to +85°C. For more demanding industrial applications, it is -40 to 125°C. The platinum layer remains completely stable within this range and does not undergo any changes. However, some platinum pastes need to work under long-term high temperatures, some even up to around 1000°C. Some users have reported that the test resistance changes over time, typically showing an increase in resistance. Depending on the application environment, we have developed different paste types to meet various requirements.

55H-1805, fired at 850℃, with good cost-performance ratio

55H-1803, after firing at 850℃, the resistance is relatively small

55H-1803D, fired at 1150~1250℃, can meet the requirement of long-term operation within 1000℃.

For other working environments, new models can be developed according to the requirements.

This document was edited and compiled by the process engineer of Shenzhen Saiya Electronic Paste Co., Ltd. Please indicate the source if you wish to forward it.

① For more information on electronic pastes, please visit our company's forum. https://www.sryeo.com/list/4.html,

② Add WeChat: 13510026516, Master Guo, to obtain professional support in terms of slurry.

③ Follow our official account: Shenzhen Saiya Slurry