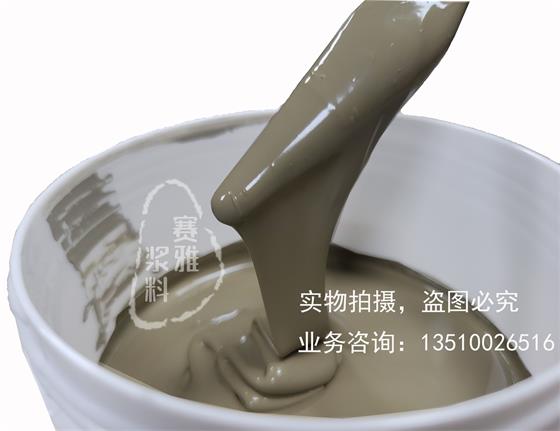

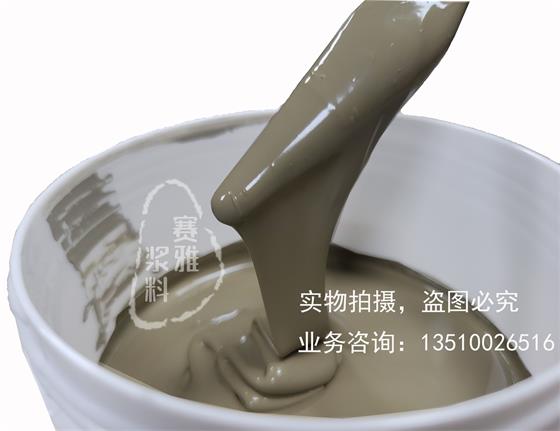

Conductive silver pasteThe silver paste in the middle is a viscous paste composed of a mechanical mixture of fine particles of high-purity (99.9%) metallic silver, adhesives, solvents, and additives. The conductive silver paste has very strict requirements for its constituent substances. The purity, content, shape, and size of it are all important factors.Silver pasteThe performances are all closely related.

The metallic silver particles are the main component of conductive silver paste, and the conductive properties of the film switch are mainly achieved through them.

The content of metallic silver in the slurry is directly related to the conductivity. In a sense, a higher silver content is beneficial for improving its conductivity. However, when the content exceeds the critical volume concentration, its conductivity does not increase. Generally, when the silver content is between 80% and 90% (by weight), the conductivity has reached its maximum value. As the content continues to increase, the electrical property does not improve anymore, and the resistance value shows an upward trend; when the content is below 60%, the resistance changes are unstable. In specific applications, the silver particle content in the silver paste should take into account both stable resistance values and be constrained by factors such as curing characteristics, bonding strength, and economy. For example, if the silver particle content is too high, the probability of being coated by the connecting resin is low, and the adhesion of the silver conductor after curing into a film decreases, with the risk of silver particles falling off. Therefore, the silver content in the silver paste is generally suitable at 60% to 70%.

The size of the silver particles is related to the electrical conductivity of the silver paste. Under the same volume, larger particles have a lower chance of contact between each other and leave larger spaces, which are occupied by non-conductive resins, thus blocking the conductive particles and reducing the electrical conductivity. On the contrary, smaller particles have a higher chance of contact, and the electrical conductivity is improved.

The influence of particle size on conductivity, as shown above, is merely a relative relationship. Due to the effects of processing conditions and screen printing methods, it is necessary to ensure that the particles can smoothly pass through the mesh holes of the screen while also meeting the processing conditions for silver particles. Generally, a particle size of 3 to 5 μm is already very good. Such a particle size is only equivalent to 1/10 to 1/5 of the mesh diameter of a common 250-mesh screen. It enables the conductive particles to pass through the mesh holes smoothly and deposit densely on the substrate, forming a full conductive pattern.