For electronic conductive pastes such as silver paste, platinum paste, and resist paste, do they require a diluent? If so, how much should be added and how should it be added? Will it have any adverse effects on the paste? How to select the appropriate diluent for pastes of different systems?

Many users who use electronic pastes often have such questions after receiving the goods: Do I need to add a diluent to the paste? How much should I add? The electronic pastes mentioned here refer to types such as silver paste, conductive adhesive, resistor paste, dielectric paste, and so on.

Is it necessary to add a thinner? Not necessarily. It depends on the consistency of the slurry and the construction process to determine jointly. 1. Generally, the viscosity of the slurry when it leaves the factory is usually appropriate or slightly higher. Corresponding to this, the construction process is such that usually no thinner is needed and it can be used directly. However, for the same slurry, some users prefer to lower the viscosity. In this case, a thinner needs to be added. 2. In engineering usage, due to the evaporation of the solvent in the slurry, it will become increasingly dry. Therefore, during use, a little thinner needs to be added to reduce the viscosity and improve the printing effect. There are also some special processes. For example, using the spraying process, a relatively large amount of thinner needs to be added to facilitate the discharge of the material and control the surface smoothness, as well as controlling the thickness of the film layer.

Will adding a diluent affect the performance of the slurry? For silver paste, adding a certain proportion of diluent will not have a significant impact on the silver paste. Based on the actual situation, it is generally recommended that the addition should not exceed 3% by weight. The method of addition is particularly important. When adding, it should be done gradually, and fully mixed before deciding. It is strictly forbidden to add too much at once, as excessive addition will cause the silver paste to become too dilute and make it impossible to apply. If the viscosity is too high, it can be diluted; if the viscosity is too low, there is no way to thicken it. Basically, it will be scrapped. For resistive paste, the addition amount is even more crucial. Adding too much will not only affect the convenience of application, but more importantly, it will change the resistance sheet resistance value, resulting in poor consistency of the sintering film resistance. For the conductive adhesive used for bonding chips, excessive addition will lead to an increase in the emission volume during drying, affecting the density of the cured layer, adhesion, and the strength of the chip and lead.

How to select the appropriate diluent for different types of slurry?

At present, the electronic conductive pastes are mainly composed of oily materials, and the diluents are mainly organic solvents, including various alcohols, esters, ethers, and various ketones. The selection of solvents needs to take into account factors such as environmental protection, pollution, labor protection, and temperature.

First, let's categorize the electronic pastes based on the curing temperature. There is one type that is cured through low-temperature baking, which generally refers to the process where the paste cures naturally from room temperature up to 200-300 degrees Celsius through drying. Low-temperature baked pastes are mainly composed of resins and conductive functional materials. Their own curing temperature is relatively low, so when choosing the diluent, solvents with lower volatility points, such as ketone products, should be selected. For example, our company's ST1003 is specifically designed as a diluent for this type of paste, with a very small odor and basically no harm to the human body.

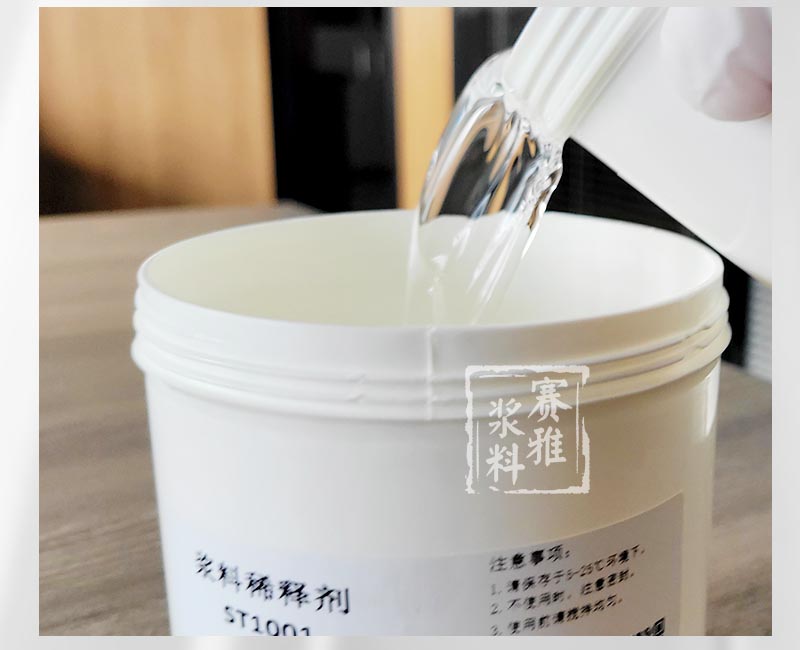

One type is the high-temperature sintering type slurry, which generally refers to the type that undergoes sintering at temperatures above 400 to 500 degrees Celsius up to over 1,000 degrees Celsius. For this type of slurry, alcohols and ethers with higher volatility are chosen as diluents. The most commonly used one is camphor alcohol, which can be universally used in various types of slurry (silver slurry, resistance slurry, dielectric, etc.). However, at present, camphor alcohol has two drawbacks. Firstly, it has a strong smell, even after secondary purification, there is still a significant smell. Secondly, its viscosity is relatively high, meaning that a larger amount of it is needed to achieve the required viscosity. Our company has conducted years of experimental research and has chosen the dedicated diluent ST1001. Its characteristics are clear and transparent like water, with a faint fragrance, low viscosity, and good wetting effect with the slurry (it is also one of the components of the slurry).

In addition, water-based pastes are rapidly gaining popularity. They have inherent advantages in the field of environmental protection as they use pure water as the diluent.

Often, my friends would come to me asking, "After work, I don't know what to use to clean the net plate. No matter what I do, I just can't clean it thoroughly. What would be the best way? Let's talk about it next time."

Original article. Please attribute the source when reusing!

For more information on electronic pastes, please visit our company's forum. https://www.sryeo.com/list/4.html,

You can also add the WeChat ID: 13510026516 to get professional support in terms of the slurry. Mr. Guo.