Specification

|

Product: |

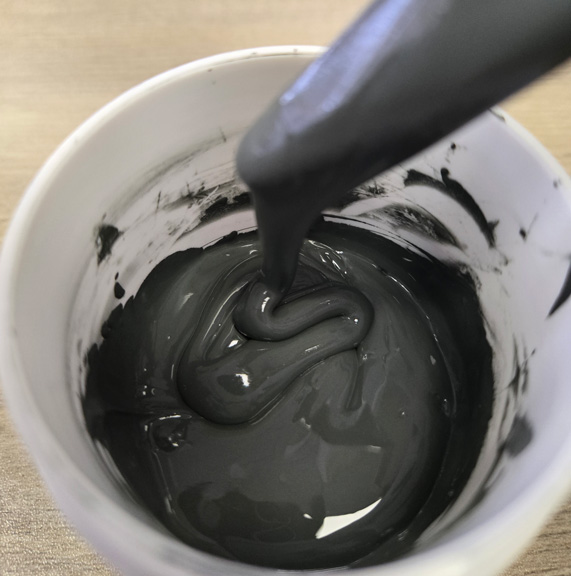

Mo/Mn paste |

|

Part number: |

65H-1805 |

Application:

Molybdenum-manganese electronic paste is a printable thick-film conductor electronic paste that can be used as a surface conductor layer for aluminum nitride, silicon nitride, beryllium oxide, and aluminum oxide substrates.

The main features are as follows:

It has the same shrinkage rate as ceramics, and the bonding strength between sintered material and ceramics is excellent. It can meet the requirements of printing and small hole filling processes.

The metal particles have good dispersion properties and the metalized surface should be flat.

Operating conditions:

|

Substrate |

Alumina ceramic |

|

Printing |

200-250 mesh stainless screen |

|

Levelling |

5-15min minutes at room temperature

|

|

Drying |

Place in an air circulation oven and bake at 100-150℃ for 10-15 minutes (the baking temperature should be below 230℃) |

|

Firing Condition |

Tunnel furnace sintering hydrogen atmosphere, the peak of 1300~1550 ℃ (recommended), at peak of 3-45minutes. |

|

Thinner |

ST-1001 |

Characteristics:

Paste Characteristics:

|

Characteristic |

Standard |

Test method and conditions |

|

|

1 |

Fineness |

≤5μm |

FOG test |

|

2 |

Viscosity |

50-280Pa.s |

Brookfield HBT utility cup and spindle (SC4-14/6R), 10rpm, 25±1℃ |

Characteristics after firing:

Check fired film produced under the conditions specified in 1), (Film thickness is 8-12μm.)

|

Characteristics |

Standard |

Test method and conditions |

|

|

3 |

Resistivity |

≤25mΩ/□ |

Test pattern 0.6mm×60mm |

Storage condition and Term of validity

The productshall be guaranteed for 1 year after shipping date, keep tightly under at 5-25℃

Packaging method:

Standard package 1000g/can ,if you need sample to test, available 200g with small package.