Specification

|

product: |

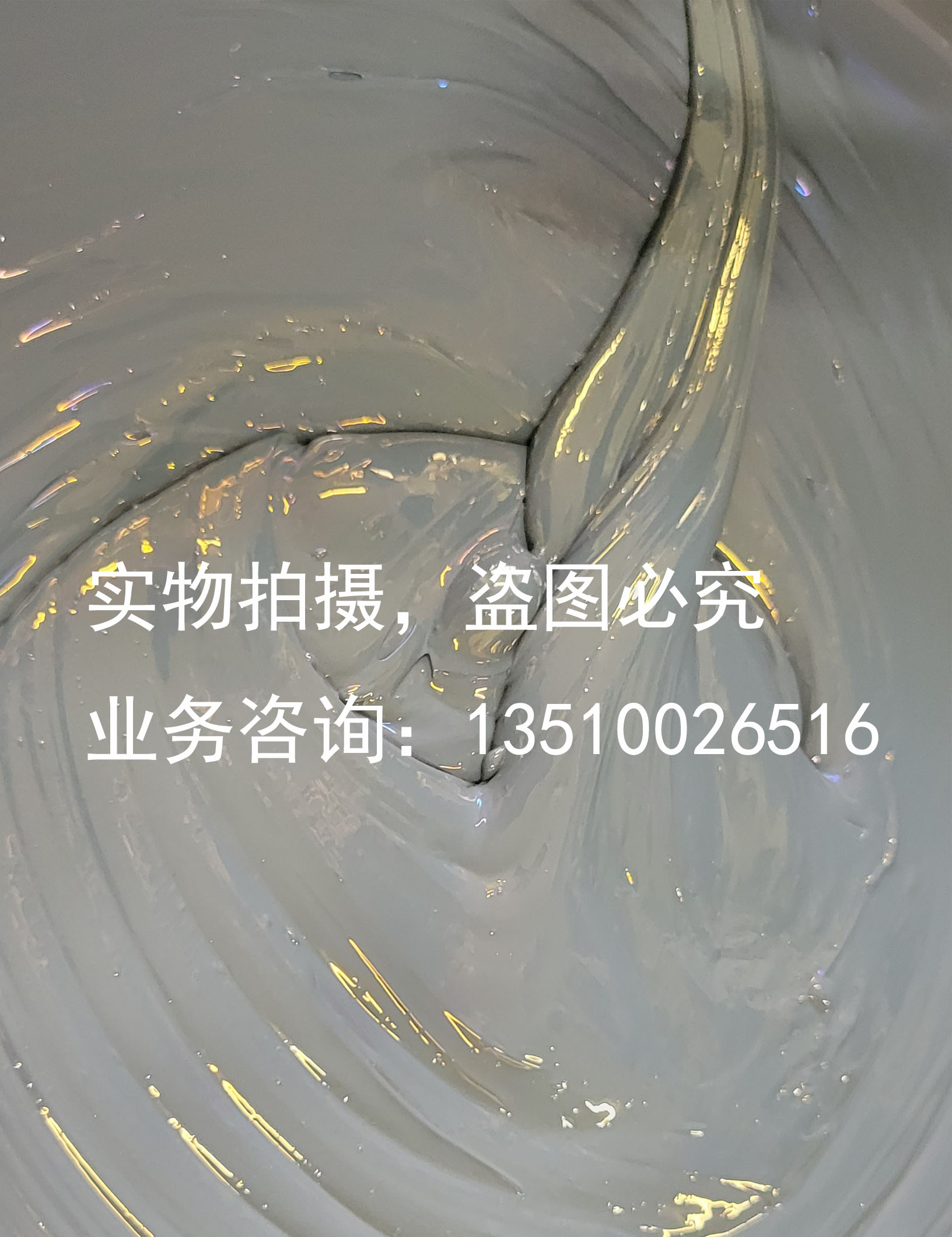

Silver paste |

|

Part number: |

01H-4205 |

Application:

Suitable for ceramic capacitor electrode.

Operating conditions:

|

Substrate |

Ceramic capacitor |

|

Printing |

200-300 mesh stainless screen |

|

Levelling |

5-15min minutes at room temperature |

|

Drying |

100-150℃ 10-15 min |

|

Firing Condition |

Atmospheric firing in belt furnace with peak time of 9-11 Minutes at 850℃ |

|

Thinner |

ST-1000 |

Characteristics:

|

|

01H-4205 |

|

|

|

|

|

Fineness(um) |

≤5 |

|

|

|

|

|

Viscosity(pa.s) |

120-280 |

|

|

|

|

|

Silver content(%) |

70-75 |

|

|

|

|

|

Resistivity (mΩ/□) |

≤5 |

|

|

|

|

|

Adhesion (N) |

≥55 |

|

|

|

|

|

Standard |

Test method and conditions |

|

Fineness |

FOG test |

|

Viscosity |

Brookfield HBT utility cup and spindle (SC4-14/6R), 10rpm, 25±1℃, Brookfield HBT |

|

Resistivity

|

Fired film thickness is 8-12mm.) Test pattern 0.6mm×60mm |

|

Adhesion strength |

Peel Test: 0.5mmφ Tin plated Cu wire soldered on 2mm×2mm Pad. Solder: 96.5Sn/0.5Cu Mildly activated flux used. |

Storage condition and Term of validity

The product shall be guaranteed for 1 year after shipping date, keep tightly under at 5-25℃

Packaging method:

Standard package 1000g/can,if you need sample to test, available 200g with small package.