For detailed product specifications and parameters, please contact: 13510026516 (same number for WeChat)

The platinum paste is a uniform paste-like material formed by mixing pure platinum particles, organic substances and binders. Platinum has extremely stable metallic properties and plays a crucial role in sensor electrodes and high-temperature co-fired components.

Construction process:

Construction techniques.

This series of platinum paste is suitable for most application scenarios. It can be used for screen printing, dispensing, or simple manual application. After printing, it should be left for 5 to 10 minutes.

2. Dry it and place it in an oven at 150℃ for 10 minutes (the step of sintering in a chain-type tunnel oven can be omitted).

3. Sintering: The temperature rises at a rate of 5 to 8 degrees per minute, with the peak minimum temperature being 850 degrees Celsius, lasting for 10 minutes. (Depending on the actual process requirements, it can be heated up to 950 degrees Celsius. Higher sintering temperatures will result in better film layers and smaller resistances. Using platinum paste in many cases requires the stability of platinum at high temperatures. Therefore, the platinum paste can be heated up to 1400-1500 degrees Celsius, and the film layer will still be relatively stable. When using it, different sintering temperatures can be selected as needed, and the platinum paste can handle all of them.)

4. Temperature resistance performance. The platinum layer remains completely stable and does not undergo any changes within the temperature range of -40 to 125 degrees Celsius. However, some platinum pastes need to work at high temperatures for a long time after being sintered, and some even need to remain at around 1000 degrees Celsius for an extended period. We have developed different paste types to meet the requirements of various environments.

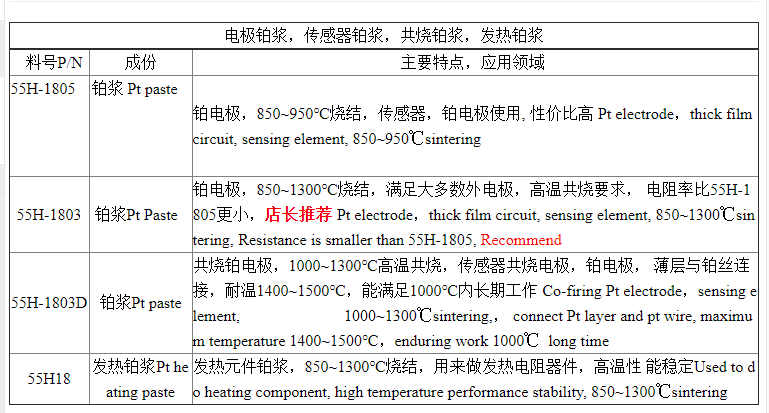

55H-1805, fired at 850℃, with good cost-performance ratio

55H-1803, fired at 850℃, has a relatively low resistance. The store manager recommends it.

55H-1803D, fired at 1000~1250℃, can meet the requirement of long-term operation within 1000℃.

Specification

|

product: |

Alumina ceramic board heating Resist paste |

|

Part number: |

55H18 |

Application:

The resist paste applies to alumina ceramic heating resistor paste.

Operating conditions:

|

Substrate |

Alumina ceramic |

|

Printing |

200-250 mesh stainless screen |

|

Levelling |

5-15min minutes at room temperature |

|

Drying |

100 |

|

Firing Condition |

Atmospheric firing in belt furnace with peak time of 10 Minutes at |

|

Thinner |

ST1001 |

Characteristics:

Paste Characteristics:

|

Characteristic |

Standard |

Test method and conditions |

|

|

1 |

Fineness |

≤8μm |

FOG test |

|

2 |

Viscosity |

120-280Pa.s |

Brookfield HBT utility cup and spindle (SC4-14/6R), 10rpm, 25± Brookfield HBT |

Characteristics after firing:

Check fired film produced under the conditions specified in 1), (Film thickness is 8

|

Characteristics |

Standard |

Test method and conditions |

|

|

3 |

Appearance |

Compact and unknit |

Eyeballing |

|

4 |

Resistivity |

As below form |

Standard film thickness is |

|

TCR |

As below form |

HTCR 25 |

|

| Product series |

Alumina ceramic board heating Resist paste |

|||

|

P/N |

resistivity (Ω/□) |

TCR (ppm/℃) |

Sintering |

viscosity (kcps) |

|

55H18-0R03030 |

0.03 |

3000 |

850 |

150-300 |

|

55H18-0R04030 |

0.04 |

3000 |

||

|

55H18-0R05030 |

0.05 |

3000 |

||

Storage condition and Term of validity

Packaging method: